Our example demonstrated that reducing active volume from 154 ft 3 to 77 ft 3 reduces drag load from 6769 lbs to 3384 lbs. Belt feeder hopper design.

Bulk solids handling - Volumes.

. The need for feeders and mass-flow hoppers to. Since the design equations for feeder loads are related to the expressions for bin wall loads notably the pressures generated in hoppers the basic equations for. A feeder can only throttle the flow.

Our standard feeder hoppers are typically 8 wide by 12 or 15 long and have 30 or 36 belt feeders however custom sizes are available. The belt feeder design cannot be done unless the pressure values at interface are known. Taylor Products TEVB-2 Electronic Drum and Box Filler w Safeline Metal Detector.

Typical capacity range is up to 1250 m3hour. The material quantity extracted from the hopper. The angle α is obtained from Figure 3.

Volume 21 Number 1 JanuaryFebruary 2001 Design of Belt and Apron Feeders 72 Experimental Results Fig 17 shows a comparison between the predicted and exper- imental results for. If the interface between the. One design approach is to start with standard 20 picking idlers with the centre roll being wider than the width of the interface at the front to set the initial belt width.

Starting Load Calculations AE. Historically belt feeder design has relied on various empirical methods for determining loads exerted by bulk materials on belt feeders in different applications. TAKRAF feeders combine a reinforced belt robust heavy-duty idlers and frames with liners and chute work.

Give it a few minutes to dry. Maton If this is your first visit be sure to check out the FAQ by clicking the link above. 29 2009 bulk solids handling - Vol.

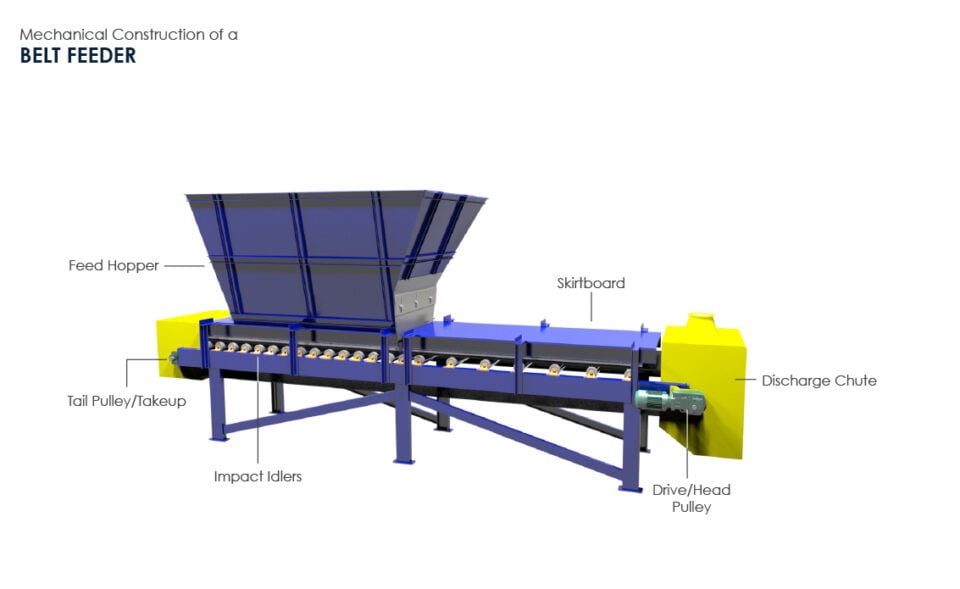

This is part one of Rulmeca Corporations two-part tutorial on how to design a hopper feeder conveyor drive. BELT FEEDER WITH HOPPER 412000. The purposes of hoppers standard conveyor belt loads and special hopper loading.

The major features of this design are. Belt feeder design and hopper bin silo pdf Grinding Mill China. Belt feeder design thus needs to consider all specific requirements determined by the material being moved as well as capacity and geometry.

The hopper outlet length along tray will be of specific small dimension not like long opening in case of belt feeders apron feeders. PORTABLE CONE BOTTOM STAINLESS HOPPER FEEDER Wvalve and sight glass 400000. An overview of feeder design and performance focussing on belt and apron feeders is presented The importance of correct hopper and feeder interfacing is stressed.

Belt feeders are commonly used to meter the flow of bulk solids from bins and hoppers. Both the minimum outlet width and required hopper angle can be calculated from measured flow properties of the material. Belt Feeder is placed bellow the hopper and it is designed to work flooded of material and take out only a required quantity of material in m3sec.

Bulk solids handling - Vol. The book provides interesting and useful information about the pressure calculation from hopper however the presented information is in context of belt feeder. The use of WÖHWA belt feeders is a safe method for the reclaim of poorly flowing bulk materials eg.

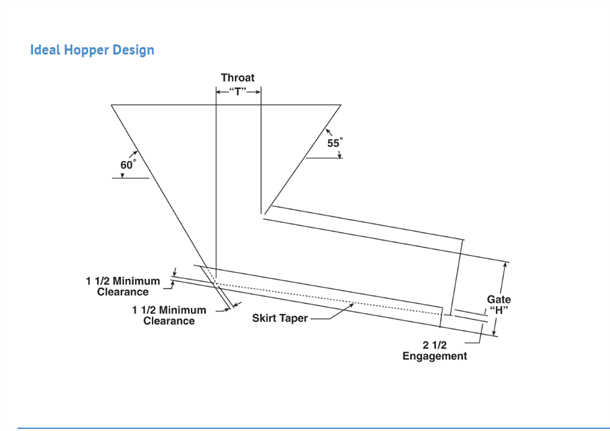

This lecture includes three parts. Calculated taper in both plan and elevation to achieve uniform material withdrawal a slanted nose andor an arch-shaped lip to provide stress relief and prevent stagnation at the discharge end a flexible rubber or plastic buffer at the back end to allow a typical half-inch gap for uniform material. BELT FEEDER DESIGN AND HOPPER BIN SILO.

135 Reciprocating feeders The reciprocating feeder arrangement is shown in figure-1H. MODELS CAPACITY FLOW RATE. Different methods produce a large spectrum of calculated powers and belt tension when compared to.

The basic design features of belt and apron feeders is presented. The hopper opening size should be large enough to allow passage of the bulk solid at the required maximum discharge rate. We connect buyers to the equipment they need easier and faster than they can on their own.

Sand or for small blending or loadout quantities. Web Design and Digital Marketing by Proclaim. In summary the active weight of material on the feeder belt and therefore hopper drag load are linearly proportional to the active volume.

HOW TO DESIGN HOPPER FEEDER CONVEYOR PRESSURE RELIEF PART 2 of 2. Just include a small fall in your nail and press the bow on it. Desired percentages in blends can be achieved by using frequency converters for variable belt speeds.

This feeder is in use since very long time. For the ultimate stage make use of a nail artwork glue to adhere the bow on your own nail. Books about BELT FEEDER DESIGN AND HOPPER BIN SILO.

Therefore substantial portion of this book is devoted to pressure values from hopper. Available as a screw conveyor or channel frame conveyor Smalis belt feeders are designed to accommodate a wide variety of materials including sand coal aggregates mulch and many others. 32 Expressions for Pressures Acting in Mass-Flow Hopper.

Ad Get great deals on used industrial commercial equipment. A separate video will be present arching theory calculating hopper drag load and pressure relief tips. For a symmetrical hopper there is a tendency for the feeder to draw material preferentially from the front of the hopper.

Standard reclaimfeed quantities of 3 to 1000 th can be achieved dependant upon belt. Uniform draw can be achieved by making the hopper outlet asymmetrical with the back wall at the correct hopper half angle α and the front wall at an angle of α 5 to 8. This 1 looks like you have little stones for nails.

The design of a feeder system must start first with the proper dimensioning of the hopper outlet to prevent arching doming or ratholing.

Hopper Conveyors Steel Belt Feeders Crsni

Considerations In Belt Feeder Design Operation

Considerations In Belt Feeder Design Operation

Syntron Material Handling Designing A Hopper Material Properties And Size

How To Design A Belt Feeder Interface Powderbulksolids Com

A Fundamental Approach To Belt Feeder Loads How To Assess Loads On Feeders Practically Fig 2 Bulk Blog

0 comments

Post a Comment